Welcome to customize all kinds of clothing

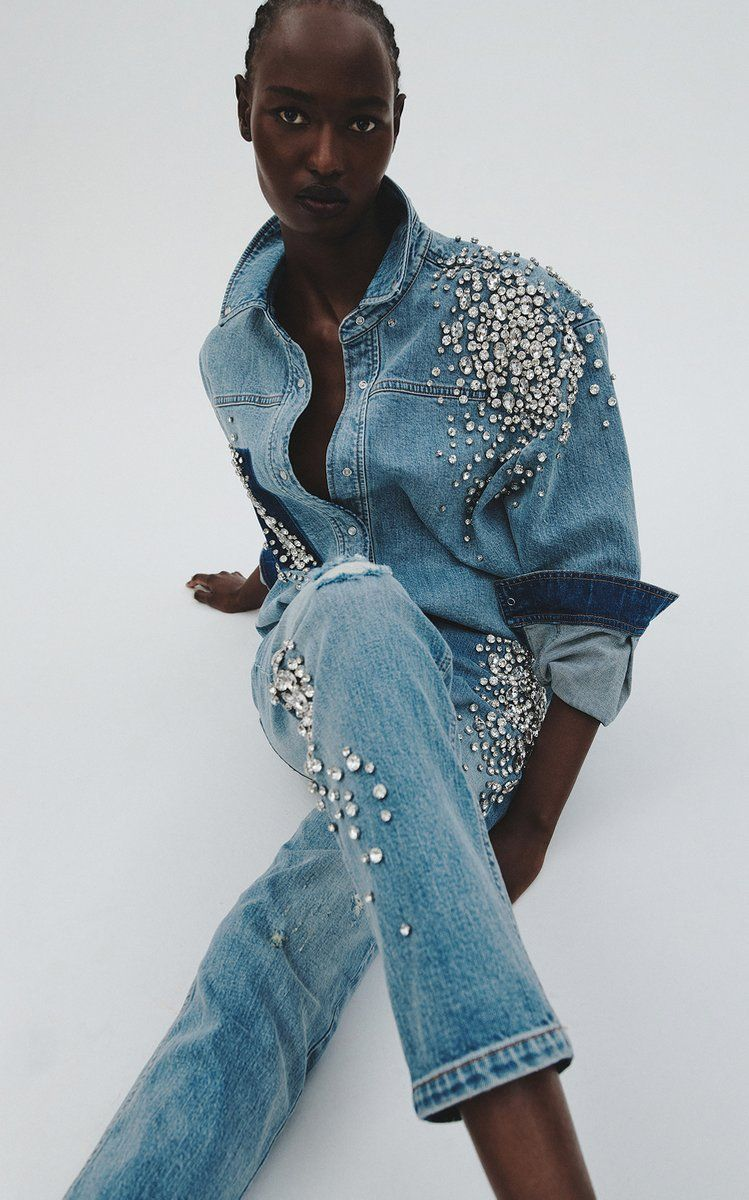

Custom Embellished Denim: Inside the Bedazzled Jeans Clothing Production Plant

Introduction: The Rise of Sparkling Denim

In today’s era of personalized fashion, custom embellished denim—especially bedazzled jeans—has transitioned from red-carpet exclusivity to a statement piece in everyday wardrobes. Our “Bedazzled Jeans Clothing Production Plant” perfectly merges industrial precision with handmade artistry, creating each pair as a unique, sparkling denim masterpiece.

Phase One: Design Development & Pattern Planning

Digital Design First

Our production process begins with digitizing designer creativity. Using CAD software, we precisely map out embellishment layouts, ensuring each crystal, stud, or embroidered element finds its optimal position on the jeans. This stage emphasizes balance in embellishment distribution, aiming for both visual impact and wearing comfort.

Material Selection

We use only high-quality denim as our canvas, paired with embellishments like Swarovski crystals, premium alloy studs, and colorfast embroidery threads. All materials undergo durability testing to ensure embellishments withstand daily wear and repeated washing.

Phase Two: Precision Cutting & Preprocessing

Laser Precision Cutting

Laser cutting technology ensures clean edges on every piece, laying a solid foundation for subsequent embellishment. Areas requiring extensive decoration are specially reinforced to prevent fabric distortion.

Positioning Marking System

Using heat-erasing ink or laser marking, we precisely mark each embellishment point on the cut pieces, with tolerances controlled within 0.5 mm—a key technique for achieving consistency in complex patterns.

Phase Three: Multi-Layer Embellishment Techniques

Automated Embellishment Technology

For repetitive patterns, semi-automatic setting machines precisely fix crystals in place. Programmed to follow design patterns, these machines place hundreds of crystals per minute, significantly boosting production efficiency.

Handcrafted Artistic Embellishment

For intricate patterns and special designs, our experienced artisans use specialized tools to hand-set each crystal and stud, ensuring flawless placement from every angle. This process can take hours or even days, depending on the design’s complexity.

Hybrid Embellishment Techniques

Our unique “hybrid embellishment production line” combines:

- Machine embroidery with crystal setting

- Heat-transfer patterns layered with 3D decorations

- Contrast designs featuring distressed finishes and localized sparkling elements

Phase Four: Assembly & Quality Inspection

Professional Sewing

Embellished pieces move to the assembly line, where skilled sewers use reinforced stitching techniques for joining. Special stitches and reinforced materials are applied to heavily embellished areas.

Seven-Stage Quality Inspection System

- Embellishment Durability Test: Simulates wear friction to ensure embellishments stay secure

- Pressure Test: Specific stress testing on densely decorated areas

- Wash Test: Simulates multiple washes to check embellishment retention

- Colorfastness Check: Ensures embellishments do not fade or bleed color

- Safety Inspection: All embellishment edges are smooth and pose no wear risk

- Visual Symmetry Check: Multi-angle inspection for pattern balance and overall aesthetics

- Final Wear Assessment: Real-person fitting ensures both comfort and visual appeal

Phase Five: Custom Services & Sustainable Development

Personalized Customization Process

We offer multi-tier customization services:

- Basic Customization: Choose from preset patterns and embellishment types

- Advanced Customization: We translate client design concepts into technical reality

- Full Personalization: Client decides everything from fabric selection to individual crystal placement

Eco-Friendly Production Commitment

- Use of recyclable embellishment materials

- Wastewater treatment systems for environmentally responsible production

- Scrap material recycling program

- Comprehensive use of low-energy production equipment

Industry Innovation: Technology & Future Trends

Smart Embellishment Technology

We are developing techniques to integrate micro-LEDs with crystals, creating interactive illuminated denim. Additionally, we are exploring thermochromic crystals and light-sensitive materials that allow jeans to change appearance based on environment.

Rapid Response Production System

Through IoT technology, our production line enables flexible, small-batch, multi-variety production, meeting fast market demands for personalized products.

Conclusion: The Fusion of Art & Craftsmanship

Custom embellished denim production is not just garment manufacturing—it’s a sophisticated blend of artistic creation and industrial technology. Our bedazzled jeans production plant represents the future of denim manufacturing, integrating personal expression, masterful craftsmanship, and sustainable production.

Every pair of bedazzled jeans from our plant is more than just clothing—it’s wearable art that carries design philosophy, craft spirit, and wearer personality. From machine precision to artisan touch, we ensure every piece shines with unique brilliance.

Explore More Articles from WUYI Apparel

Want to learn more about styling essentials hoodies or other apparel tips? Check out some of our other helpful articles:

- Wearing Black to a Wedding: A Modern Etiquette Guide

- Rainwear Jackets: The Perfect Fusion of Fashion and Function

- How To Measure Clothes

- Casual clothing – Casual and elegant through everyday life

- How to Find Your Style:An in-depth exploration of one’s own clothing style

For more tips and tricks on fashion and lifestyle, don’t forget to visit our Blog Section.

Head over to our Shop Page to browse our full collection and pick your favorite essentials hoodie today!